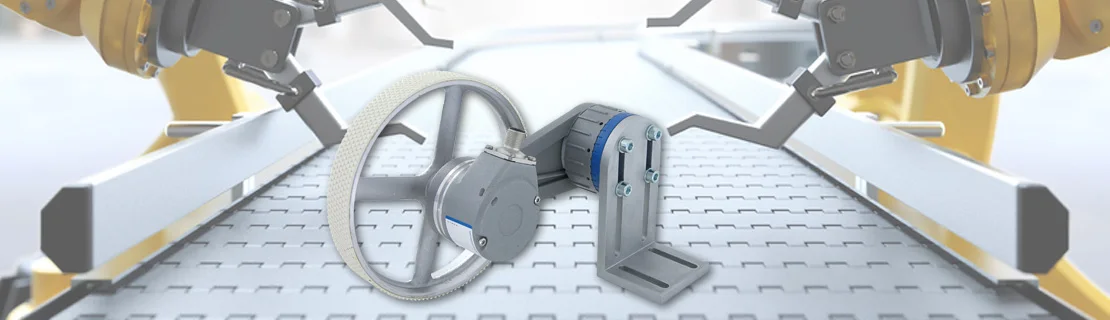

LMSCA the ultra compact and robust length measuring system

including encoder WDGP 36A and 200 mm measuring wheel

- Space-saving and reliable complete system for position, speed and length

- Up to 0.0125 mm/pulse for excellent measurement results

- Suitable for many surfaces

- Absorbent mounting

- Contact pressure – easily adaptable by intelligent central adjustment

- Quickly mounted and adjusted

The patented tooth grid has been developed for simple and definite mounting for a longer service life. The LMSCA is rigidly mounted using the multiple mounting options, with the measuring wheel placed loosely on the moving material. The teeth are loosened with only one central screw, which is secure against loss, and a defined force of the measuring wheel is applied to the material with the tooth grid.

Compared to other systems without this method, it depends on the skill of the assembler how much force is applied to the material. Depending on the surface of the material, you want to select the contact pressure as high as possible in order to exclude possible slippage and, on the other hand, you don’t want to damage the material or the surface of the measuring wheel. With the toothing, you can give the technician a clear specification of how high the contact pressure should be, with up to 20 N in steps of 5 N. The spiral spring design ensures that the contact pressure is as high as required to avoid possible slippage.

The designed spiral spring ensures that the set contact pressure is permanently applied and also elegantly compensates for larger unevenness and ensures contact with the material at all times.

Depending on the desired area of application, the system with its detailed solutions offers some great benefits.

Small, compact and very accurate:

The LMSCA is only 120 mm long and equipped with a 36 mm diameter rotary encoder. The rotary encoder can provide (depending on the order number) 1 ppr up to 16,384 ppr and thus supplies the right number of pulses for your application. The LMSCA length measuring system achieves a resolution of up to 0.0125 mm/pulse. Alternatively, as an absolute encoder with the patented QuattroMag singleturn technology and EnDra - multiturn technology, the encoder can send e.g. CAN messages, RS 485 or SSI signals.

Can be mounted anywhere:

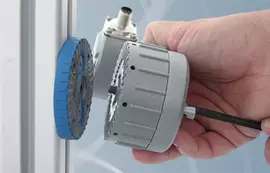

The encoder is fixed by a clamp, which allows the connector outlet to be positioned as desired. The encoder has a radial connector outlet. A mounting bracket with 2 elongated holes and a cross hole offers every freedom to mount the LMSCA perfectly.

Suitable for any surface:

The measuring wheels with a circumference of 145/200 mm have different surfaces for use on all materials, such as plastic, PVC, painted surfaces, paper, cardboard, metal, textiles, carpet, rubber, foil, etc. with a contact pressure of up to 20 N in 5 N increments that can be precisely adjusted via the grid for optimum protection of the material vs. contact pressure.

Can be used everywhere:

The robust construction and the durable and stable bearing of the swing arm and the encoder are designed for a wide range of applications. Wherever a speed or position is to be measured, such as on an assembly line, in continuous production/measurement or in reversing movements at greater distances, the LMSCA is suitable as a reliable sensor.

- In-line speed measurement for high quality marking of wood, cardboard boxes or packaged food or medicines with e.g. Date Code, Expired Date, Lot, etc.

- In-line speed measurement for quality monitoring with cameras of e.g. foils, carpets, cables, laminates, pipes, décor.

- In-line distance measurement for the determination of volume and tons with an additional sensor, e.g. for parcel services or in quarries.

- In-line speed measurement for gluing cardboard boxes or foils

- Speed and position measurement for storage and retrieval machines can also be realised with a pinion and a toothed rail

The compact LMSCA has a high protection class of IP67, at the shaft input IP65, is supplied with 4.75 to 32 VDC, delivers ABN and inverted signals in TTL or HTL or CAN, J1939, SSI or RS485 and can be connected via an M12 connector.

用长度测量系统LMS MA精确定位

可选增量或绝对值WDGI / WDGA编码器

- 节省空间、可靠的完整系统用于位置、速度和长度测量

- 高达0.008mm/脉冲(增量,完整的系统)或

高达0.003mm/步(绝对值,由独立部件组成:测量轮,弹簧杆及编码器)以获得卓越的测量结果。 - 适用于各种表面材质

- 快速安装和调整

位置、速度、位移

...稳定且精确地测量

在超过25年的时间里,Wachendorff开发和制造的测量系统和旋转编码器在全球广泛应用于机械和设备工程、电梯行业、移动机械和可再生能源领域。

超过1500个已实现的客户特殊定制证实了我们的灵活性,并绝对专注于客户需求。由于我们的旋转编码器和测量系统极高的机械和电气稳定性,我们提供了5年的质保——这在世上是独一无二的!

我们从建设阶段就给您提供支持。我们的优势在于为您的测量任务提供精确匹配的长度和位置测量系统。

我们从结构开发阶段对您进行技术支持。我们致力于精确配合的长度和位置测量系统来完成您的测量任务。

有了这些系统,一些设备的位置、速度和位移,例如传送带、薄膜/纸网或纸板包装,就可以安全有效地被记录下来。

理想状态下,使用LMSMA2x/3x测量系统,可以满足极高的测量需求:

在大多数多样化的环境中,由于以下原因,通过LMSMA2x/3x最理想的、低速滑动的测量,可以得出稳定精确的测量结果:

- 弹簧杆压力可调

- 对不同的表面,有不同材质的测量轮可选

- 分辨率从1.0至0.008mm/脉冲可选(增量,完整的系统)

或高达0.003mm/步(绝对值,由独立部件组成:测量轮,弹簧杆及编码器)

设计紧凑,满足了狭小空间的安装要求。由于所有原件的高机械稳定性,有较长的使用寿命。可在机器上快速灵活地安装。

细节体现经验…使用测量系统节约时间

在使用中心弹簧臂基础上,我们显著优化了整个系统调整的可能性。这将为客户提供有建设性和有价值的利益:

36个位置校准

新开发的手轮,其将360°以10° /格的分辨率划分,能校准36个位置。与角度支架的延长孔组合,将有更多的空间进行安装。

预载力易调节

新的系统中,弹簧预载力是可以调节的,可从5N调节到最大预载30N

无需拆卸调试

在机器安装过程中,测量系统可处于预安装状态,或在设备调试过程中,测量系统可无需拆卸。

固定在静止位置

LMSMA长度测量系统可以将弹簧臂固定在一个静止的位置,从而当机器安装或维护的过程中,长度测量系统可处于非工作状态,当安装或维护结束后,弹簧臂可返回到工作位置,并在预先设置的压力下继续工作。你会发现有很多理由去使用LMSMA长度测量系统。

在机器上直接快速安装

LMSMA2x长度测量系统

安装非常简便,只需松开手轮的底座,并把它装在机器上的任何位置。

蓝色底座上安装孔的尺寸适用于目前市场上标准的附件尺寸。中心的锁紧螺丝能使测量系统连接到底座。现在,只需要调整预载并拧紧中心螺丝,安装就完成了!

Perfect grip and extremely low concentrical tolerance

The length measuring system LMSMA with the measuring

wheel KW (Adapter for encoder with conical shaft)

has been specially developed for applications requiring very low concentrical tolerance.

The optimised system has up to 10 times better concentrical tolerance than a standard length measuring system and is therefore suitable for applications requiring very high accuracy. In combination with our high-resolution incremental encoders an unbeatable team.

这套系统由WDGI系列增量编码器,接触压力25N的编码器支架和一个防滑的测量轮组合而成,用于持续测量许多不同类型的标记系统的速度,通过测量可以确定产品需要被贴标的位置。

作为包装过程的最后阶段,产品贴标或标记系统使用这个准确的位置信息来进行标记,在纸板,包装,标签,瓶子和其他材料上都能获得准确和卓越的打印质量。

例如:任何形式的条码,品牌LOGO和设计图案,生产批号和销售/生产日期都可以用喷墨打印机或特殊喷墨处理。

这套测量系统的组件都是完美匹配的,能够确保最大限度的精度和长使用寿命。

- IP65/IP67 防护,WDGI编码器设计并适用各种恶劣的使用环境

- 轴向最大允许负载220N,测量系统可以安全安装,不易打滑并有很大的预紧力

- 编码器是8芯接插件连接,请选择合适的电缆连接器,比如KI867直头或者KIA867弯头连接器

- 经过专门挑选的不同的测量轮表面确保了在各种应用场合下不易打滑的特性,甚至是在很高的生产速度下。

- 编码器的支架是专门开发的,带2个槽孔可用于灵活安装

- 与高达25000ppr的高分辨率WDGI编码器的组合可以实现异常高的重复精度(0.008mm/pluse)确保了标记位置的精度。